Doug B

WoW Member

[b]Rescued Firewood[/b]

[b]Rescued Firewood[/b]

Posts: 1,938

|

Post by Doug B on Mar 3, 2010 17:28:28 GMT -6

|

|

|

|

Post by mduren on Mar 4, 2010 7:54:11 GMT -6

Doug, I have used these: "and last style www.rockler.com/product.cfm?page=10&filter=bed%20hardware" Comments: The hardware must be mortised into the wood, a lot of the strength comes from a good fit. This hardware will support a huge load Vertically but I don't know how well it will hold up to a racking load. Your design would have to keep that top bunk pretty stable. This style: "another style www.rockler.com/product.cfm?page=10230&filter=bed%20hardware" Comment: This style looks like it solves the racking load but I would mortise the side piece into the rail for extra strength. Good luck with the beds! Marv |

|

sawduster

Moderator  The Motley Crew

The Motley Crew

Posts: 1,831

|

Post by sawduster on Mar 4, 2010 8:11:50 GMT -6

I used two pairs of these on the wheelchair accessible baby bed I made some time back and still had to add some diagonal braces to prevent racking. They are very sturdy and would probably do fine with a single bed, but with bunks I would definitely want to add something to prevent racking. |

|

wisardd1

WoW Member

Account Removed by own Request.

Account Removed by own Request.

Posts: 261

|

Post by wisardd1 on Mar 4, 2010 11:13:20 GMT -6

I used the third one. The first one seems beefier, but for a Mission style bed, the third one was perfect.

|

|

Doug B

WoW Member

[b]Rescued Firewood[/b]

[b]Rescued Firewood[/b]

Posts: 1,938

|

Post by Doug B on Mar 4, 2010 17:26:25 GMT -6

Thanks guys. I am leaning towards the 3rd ones but like you all have mentioned, I'm especially concerned about racking on the upper bed. The locking mechanism on the second one looks helpful, but I did not like that it was just screwed onto the bed rail.

I think I'm going to include some bed "slats" that will run between the side rails, but that would just slide into place perpendicular to the rails. That should prevent racking and also provide good support for a plywood platform to sit on.

Thanks for the input. It's good to know that someone else has used some of that hardware with satisfactory results.

|

|

|

|

Post by brburns on Mar 5, 2010 9:07:48 GMT -6

I used ones like the third type too. They have been holding my king size bed together for 3 years now. The bed will NOT rack at all. If I didn't know better I would think that the bed was built solid and not with knock down hardware.

|

|

|

|

Post by cabinetman on Mar 5, 2010 10:01:09 GMT -6

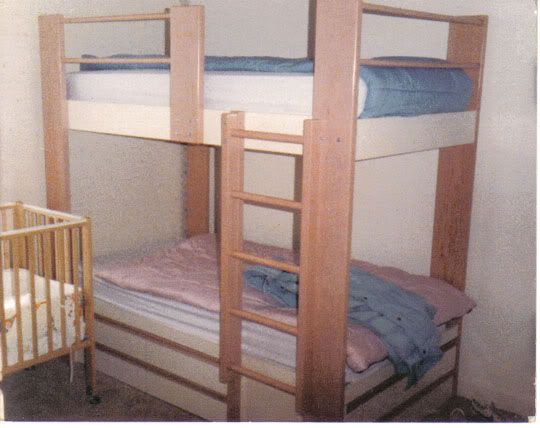

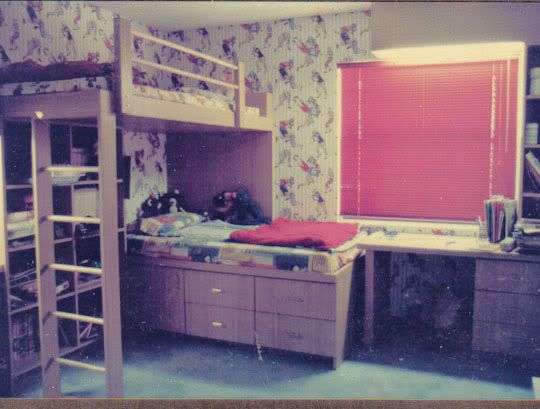

Bed rail hardware will secure the rails to a point. They can be racked. I find using mechanical fastening, like "T" nuts, or nuts and bolts, or just screwing the parts when in place provides some piece of mind. It also helps to be able to attach any parts next to a wall to the wall. That will inhibit racking. Here's a few examples. These were made to be delivered in sections and installed on the job. .  .  |

|

Doug B

WoW Member

[b]Rescued Firewood[/b]

[b]Rescued Firewood[/b]

Posts: 1,938

|

Post by Doug B on Mar 6, 2010 16:26:46 GMT -6

Thanks for the input guys.

I know it is silly, but I just don't want any bolts or screws showing on the bunkbeds. I think I have a plan for putting in captured slats that will prevent the racking concerns.

|

|

|

|

Post by cabinetman on Mar 7, 2010 20:03:40 GMT -6

Thanks for the input guys. I know it is silly, but I just don't want any bolts or screws showing on the bunkbeds. I think I have a plan for putting in captured slats that will prevent the racking concerns. You ask for advice, but think it's silly for a fastener to show. You also say you have a plan to prevent racking. There are ways to fabricate bed systems without fasteners that show. If you think using bed rail fasteners at the ends of the rails will be sufficient, they won't be. Fasteners on the edge of plywood or at the end of solid wood rails will eventually work loose as end grain will not support screws subjected to racking forces.. Gluing long grain solid wood to either plywood or solid wood will inhibit the deterioration of the fastener. Methods to prevent racking are necessary, but you say you have a plan. |

|

|

|

Post by Ruffnek on Mar 7, 2010 20:35:43 GMT -6

CMan,

I've noticed that in most all of the pictures you post of your past work, they were taken after the occupants had furnished the rooms with their belongings.

The kitchens have dishes, utensils, personal items in place, that bedroom above has toys, books and the like...it's obviously being lived in.

After installing your work, did you go back after a period of time to take the pics? Was the client receptive to having pics taken with their personal belongings on display?

I'm curious since the professional install/build pics that I've seen were taken right after completion, not after the occupants decorated with their personal belongings. Is that the norm for pros or just the way you preferred?

|

|

|

|

Post by cabinetman on Mar 7, 2010 21:12:54 GMT -6

CMan, I've noticed that in most all of the pictures you post of your past work, they were taken after the occupants had furnished the rooms with their belongings. The kitchens have dishes, utensils, personal items in place, that bedroom above has toys, books and the like...it's obviously being lived in. After installing your work, did you go back after a period of time to take the pics? Was the client receptive to having pics taken with their personal belongings on display? I'm curious since the professional install/build pics that I've seen were taken right after completion, not after the occupants decorated with their personal belongings. Is that the norm for pros or just the way you preferred? Of the few pictures I do have that are adorned, I think the work looks natural. Situations could be that I didn't have a camera with me when installing, or I might have had to go back for a punch list or to get a check. Clients never objected. Before my activity on forums, I wasn't one to take progress pictures. I don't think any shops did that. No time for that, just had work to do. If I knew at the time that one day there would be jerks that questioned the validity of anything, I probably would have spent more time taking pictures than doing woodwork. |

|

|

|

Post by art3427 on Mar 8, 2010 11:36:15 GMT -6

I would rate the Rockler options as #38606 -#1; 53724 - #2 and 28597 - #3. I've used 28597 once. It's problem is the mortising. The post has to be double mortised. The larger is about 1/16 deep so the plate face is flush to the surface. In the center of that mortise is a deeper mortise to give the hooks clearance to protrude into the post and then slide down to lock in place. Once the second mortise if done you only have a scant ledge of the original mortise to hold the screw and to maintain the post plate at flush to the surface. The rail piece is held in place by 2 screws sunk into end grain.

The 38606 overcomes these issues by providing edge screws on the bed rail and a much larger mortise for the post hardware. The post still has to be double mortised, but it also uses 6 screws instead of 2.

When I do beds I actually mortise the end of the rail about a 1/2" into the posts then do the mortising needed for the hardware. This, IMO, creates a stronger joint between rail and post since the downward weight of the load is transferred directly to the post instead of the hardware. In this configuration all the hardware does is pull the post and rail together. By the way, the post/ rail joint needs to be tight fitting . Any slop here will result in a shaky bed.

art

|

|

|

|

Post by Ruffnek on Mar 8, 2010 12:17:42 GMT -6

CMan, I've noticed that in most all of the pictures you post of your past work, they were taken after the occupants had furnished the rooms with their belongings. The kitchens have dishes, utensils, personal items in place, that bedroom above has toys, books and the like...it's obviously being lived in. After installing your work, did you go back after a period of time to take the pics? Was the client receptive to having pics taken with their personal belongings on display? I'm curious since the professional install/build pics that I've seen were taken right after completion, not after the occupants decorated with their personal belongings. Is that the norm for pros or just the way you preferred? Of the few pictures I do have that are adorned, I think the work looks natural. Situations could be that I didn't have a camera with me when installing, or I might have had to go back for a punch list or to get a check. Clients never objected. Before my activity on forums, I wasn't one to take progress pictures. I don't think any shops did that. No time for that, just had work to do. If I knew at the time that one day there would be jerks that questioned the validity of anything, I probably would have spent more time taking pictures than doing woodwork. I wasn't referring to progress pics. I assumed that since you say you made your living as a cabinetmaker, that you took pictures as examples of your work to show to prospective clients. I just found it odd that those pics would include personal belongings. I also thought it was a legitimate question and I never hinted at a validity issue so I can't see the reason for name calling... but whatever melts your butter, dude. You do seem overly sensitive to the issue of validity, though.  |

|

wisardd1

WoW Member

Account Removed by own Request.

Account Removed by own Request.

Posts: 261

|

Post by wisardd1 on Mar 8, 2010 12:49:10 GMT -6

Wow, this simple thread sure got over complicated!

|

|

|

|

Post by cabinetman on Mar 8, 2010 12:57:17 GMT -6

I also thought it was a legitimate question and I never hinted at a validity issue so I can't see the reason for name calling... but whatever melts your butter, dude. Dude...how could I possibly have been referring to you. You're such a nice guy, a real family man, never an innuendo, and always quoting the Bible.  |

|

|

|

Post by Ruffnek on Mar 8, 2010 16:00:32 GMT -6

Dude...how could I possibly have been referring to you. You're such a nice guy, a real family man, never an innuendo, and always quoting the Bible.  Yep, that's me. ;D

|

|

Doug B

WoW Member

[b]Rescued Firewood[/b]

[b]Rescued Firewood[/b]

Posts: 1,938

|

Post by Doug B on Mar 8, 2010 16:04:15 GMT -6

Thanks for the input guys. I know it is silly, but I just don't want any bolts or screws showing on the bunkbeds. I think I have a plan for putting in captured slats that will prevent the racking concerns. You ask for advice, but think it's silly for a fastener to show. You also say you have a plan to prevent racking. You misunderstood what I was saying Cabinetman...I was trying to say that even though I know it is silly for me to not wanting hardware showing that is the way I want to make the bunk bed - with no hardware showing. I know that is a silly requirement for a set of bunk beds, but that is the way I hope to do it. I will make sure there are no racking issues. Thanks. |

|

Doug B

WoW Member

[b]Rescued Firewood[/b]

[b]Rescued Firewood[/b]

Posts: 1,938

|

Post by Doug B on Mar 8, 2010 16:13:34 GMT -6

I would rate the Rockler options as #38606 -#1; 53724 - #2 and 28597 - #3. I've used 28597 once. It's problem is the mortising. The post has to be double mortised. The larger is about 1/16 deep so the plate face is flush to the surface. In the center of that mortise is a deeper mortise to give the hooks clearance to protrude into the post and then slide down to lock in place. Once the second mortise if done you only have a scant ledge of the original mortise to hold the screw and to maintain the post plate at flush to the surface. The rail piece is held in place by 2 screws sunk into end grain. The 38606 overcomes these issues by providing edge screws on the bed rail and a much larger mortise for the post hardware. The post still has to be double mortised, but it also uses 6 screws instead of 2. When I do beds I actually mortise the end of the rail about a 1/2" into the posts then do the mortising needed for the hardware. This, IMO, creates a stronger joint between rail and post since the downward weight of the load is transferred directly to the post instead of the hardware. In this configuration all the hardware does is pull the post and rail together. By the way, the post/ rail joint needs to be tight fitting . Any slop here will result in a shaky bed. art Oh oh. I already ordered the hardware and selected your least recommended one Art. After reading what you said about them, I understand the problem. In fact, after looking at the pictures again keeping what you said in mind, I don't see how the middle screw on the post hardware is even going to work - it looks like it would interfere with the top hook. At best, it is not going to have much meat to screw into after the mortises are made on either side of it. I'll have to take a close look at the hardware when it gets here and see if I think I can make it work in a manner I am going to be comforable with. Anyone have any great ideas on how to get around these issues so I can use the hardware? I like the idea of mortising the post 1/2" before making the mortises needed for the hardware, but that is going to leave the top of the mortise exposed when the rail is lowered into position isn't it? Ay! I'm already having buyers remorse and the hardware has not even gotten here yet.  |

|

sawduster

Moderator  The Motley Crew

The Motley Crew

Posts: 1,831

|

Post by sawduster on Mar 8, 2010 17:17:02 GMT -6

Doug, I'm not sure how accurate their renditions of the hardware are. I don't recall an issue with a screw interfering with the hooks. The biggest hassle I had with them was those darn double mortises. As to ideas, you could go with wedged through tenons for the rails to legs.  No hardware involved in those at all. |

|

wisardd1

WoW Member

Account Removed by own Request.

Account Removed by own Request.

Posts: 261

|

Post by wisardd1 on Mar 8, 2010 18:51:35 GMT -6

Nope Cody is a Jerk!

|

|